Precision Engineering for Professional Manufacturing

The KG-706 features intuitive computer-based controls and smart automation, delivering high-quality edge banding with ease—perfect for expanding shops seeking precision and efficiency.

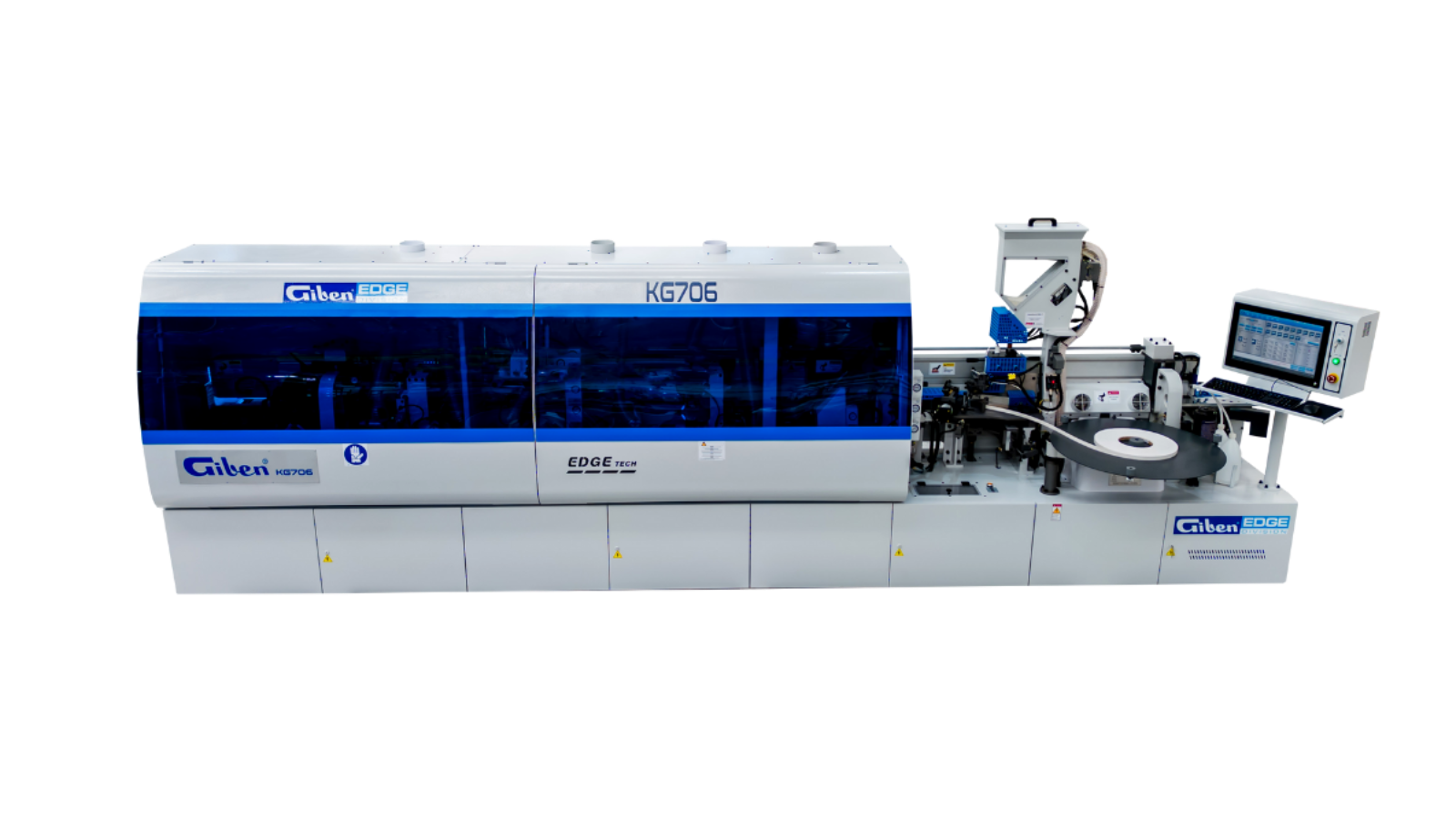

KG-706 Automatic Edgebander

Machine Overview

Heavy-Duty Performance

The KG 706 is engineered for uninterrupted, high-speed processing with a steel-reinforced modular frame, automatic lubrication systems, and premium automation throughout.

Technical Specifications:

Feed Speed: Up to 25 m/min

Edge Thickness: 0.4–3 mm

Panel Height: Up to 60 mm

Minimum Panel Size: 120 × 60 mm

Installed Power: 20.73 kW

Air Pressure: 6 bar (100 L/min)

Machine Length: 5800 mm

Advanced Processing Units

Precision Stations for a Flawless Edge Finish

From pre-milling to polishing, every station on the KG 706 is built for accuracy and speed:

Standard Configuration:

Pre-Milling Station: Squares and preps edges.

Pre-Heater: Warms edges for even glue.

Pre-Pressure Roller: Presses tape tight.

Rough Trimming Unit: Clears bulk overhang.

Fine Trimming Unit: Finishes detailed profiles.

Corner Rounding Unit: Rounds corners automatically.

Form Scraper: Removes excess material from edges.

Smart Features

Intelligent Control for Consistent Output

The KG 706 is equipped with a fully digital control system designed to optimize production flow.

Production Excellence:

7” touchscreen PC interface

Remote diagnostic access for technical support

Servo-motor positioning on key groups

Glue temperature control with standby energy-saving mode

Nesting copier system for hinge bore accommodation

Joystick adjustment for manual fine-tuning

Professional Edge Banding KG 706

Take your woodworking production to the next level with this entry-level, feature-rich edge banding machine.